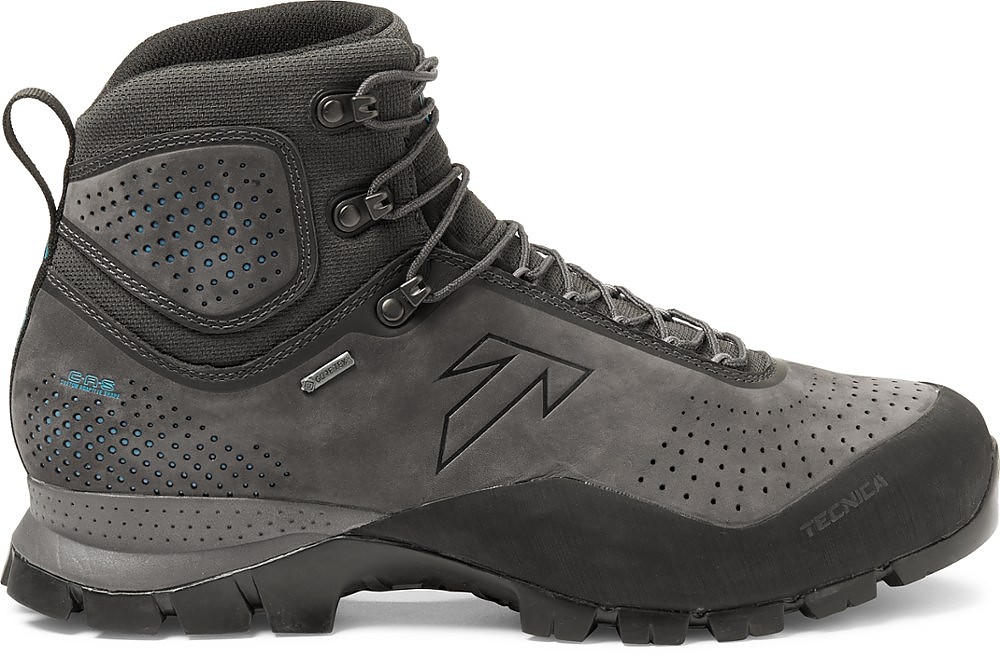

Tecnica Forge GTX

The Tecnica Forge hiking boot is a first of its kind boot borrowing fitting techniques from the ski industry to heat mold the inside of the boot to the users foot. Great for someone who has had trouble breaking in boots of similar construction or for those that have anxieties around new boot comfort.

Pros

- Comfortable out of the box

- Great reason to shop local

- Well built and will stand up to use

Cons

- Tongue design is poor and causes laces to loosen

- Not available everywhere

I tested the Forge hiking boots during the fall and winter of 2017/2018 in the northern parts of the White Mountains in New Hampshire. The weather this season provided some great opportunities to test the boots in knee deep snow, frigid as well as above normal temperatures, rain, mud, and ice. Everything you would expect in a New England winter.

These boots fell right in place in my lineup and I used them every day during hikes with the dogs as well as snowshoe and fat bike trips.

Features:

The key feature that separates these boots from others in the market is the heat molded liner. Tecnica is known for their ski boots and they are taking a play from the ski industry book. Each pair of boots will be molded to the buyer's foot before they leave the store, providing a custom fit and reduced break-in time.

I will explain the process completely but I first want to talk about the initial step in the heat molding process, driving to a retailer that sells the shoes. Tecnica is only going to release these boots to retailers that buy the molding system and one may not be near every person looking to pick these up. This step in the process may be a hurdle that is too high to overcome for some buyers and it is my understanding that Tecnica does not have plans to sell these in an online environment. However, with all that being said, I really like the idea of moving more retail to brick-and-mortar shops. This is a great way for a large brand to encourage shopping at the local level.

Assuming you have the ability to get a retailer, the processes of buying a pair and having the molded to your feet is really interesting.

It starts with the footbed being heated and then placed in a pair of “slippers” that you then put on before placing your feet in large moon-boot like bags that will be filled with air. You then sit for a few minutes with your feet being warmed by the residual heat of the footbed and your lower legs being hugged by pressurized air. The outcome of the spa like experience (stealing the phrase from OutdoorKelly, we had the opportunity to review these at the same time. Check our her take on things here.) is a footbed that is customized to your unique foot.

As you are sitting in the footbed treatment, the ankle cuff of the boot itself is being warmed.

Once the footbeds are finished, it is time to switch and put the boots on and then everything goes back in the bags. The process is then repeated so that the ankles of the boot are molded.

The entire process is wrapped up in under an hour and you are ready to hit the trail with perfectly broken in boots.

This is a pretty neat feature and is unique to this company at this point. However, after I was done, I asked myself if it was necessary and I’m not entirely sure it was. I came to this conclusion because I have never had much of an issue breaking in boots of this category in the past.

It could be possible that my foot just happens to be average enough in shape that it matches up well to the lasts most companies use to make their boots. Or it could be that most mid-weight nylon hiking boots are designed so that they are comfortable out of the box because manufacturers know that the average consumer wants to walk immediately from the store to the top of the nearest peak without getting any blisters. I personally lean towards the second reason.

Fit and Comfort:

Regardless of whether or not the heat molding made a difference for my feet these boots fit perfect and were comfortable from the start. The quality of the fit lends itself to the fact that Tecnica is using a last that has much more detail than is typically used. It has a more pronounced foot shape that makes the starting point for the shoe much closer to a normal foot.

The comfort comes from the cushioning and support that is built in to the boot. The footbeds that are included are similar to aftermarket inserts which help cushion and cradle the foot against the abuses of the trail. They are much thicker than those traditionally supplied by boot manufacturers.

Support:

The Forge boots are a hightop hiking boot with adequate ankle support. On level trails I found them to provide enough support but when things got off camber I started to feel it in my ankles. I also ran into some trouble with the design of the tongue, which I would like to see Tecnica modify down the road. The current design does not include a traditional tongue but instead has material wrap from the inside of the foot around to the outside.

In theory, this should work and I’m sure Tecnica took this design from their ski boot liners as I have seen many liners with this structure. However, ski boots have something these boots do not and that is ratchets and buckles that lock the boot in place on the ankle. These boots have laces that struggled to stay tight enough to prevent the ankle opening from becoming loose under the stress of hiking.

As the boot shifted around the ankle opening would become more and more open. This had two negative effects, the first was that I lost ankle support. The second was that the laces would become looser and looser. This was not a problem if I had quick access to my boot but it became inconvenient if I was wearing gaiters. I also think Tecnica could have spent some more time on this part of the design because users do not want to retie their boots every 45 minutes as was the case on some of my trips. This could be resolved with a different lace, but it is my opinion that the root of the problem is in the design.

Water Resistance:

These boots are Gore-tex lined and because of that they shed water and did not allow any to penetrate to my foot. The tongue is stitched so that it keeps water out to just below the ankle.

I know that there are some strong opinions about Gore-tex versus leather boots, I have both types of boots and feel there is a place for each technology. For late fall, winter, and early spring hiking and snowshoeing I prefer Gore-tex and felt that these boots were a great match to those activities. My feet were dry on the inside because they were able to breathe well, but I have not tested them out in temperatures about 45 degree Fahrenheit. As temperatures rise, I could see the concerns of swampy feet becoming more of an issue.

Traction:

The lugged sole has deep grooves and provided excellent traction in snow and mud and was adequate on ice. I was able to bite into crust layers and take steps with confidence. The lugs also shed snow and mud easily so that I did not build up gunk in my treads.

Construction and Durablity:

The Forge boots are well made and have held up against five months of daily use. In many ways they still seem brand new. The soles have shown no wear and the outer material looks pristine. I have worn snowshoes and Microspikes on most of the hikes and the boots do not show any weak spots. The laces are still strong though I have noticed some hard spots in the material from were there is a lot of friction.

Over time I would be concerned about the laces holding up and the connection that holds the lace to the boot could also be a potential weak spot. Time will tell and I will update this review if it becomes an issue.

Most important though is that the liner has maintained its form. I asked the boot fitter if the liner would break down over time and he said that it would hold its shape unless it was exposed to extreme heat and re-molded. I have been impressed by this technology and its ability to hold up over time.

Conclusions:

I have enjoyed testing the Forge boots and they have earned a place in my lineup of hiking shoes. The construction, traction, fit, and water shedding abilities all give it top marks. However, I am not sold on the heat molded technology and it is not enough to separate these boots from the rest of the field.

I would recommend these for hikers that have trouble breaking in boots of similar weight or for those that want to take all of the guess work out of a new pair of boots.

Source: received for testing via the Trailspace Review Corps

(Sample provided by Tecnica for testing and review)

The Tecnica Forge hiking boot is a heat moldable boot, integrating technology similar to that which is used in moldable ski boot liners. The Forge encourages a shift back to the way retail was done before the days of online shopping, as fittings must be done in person.

The boot is comfortable, lightweight, and has a surprisingly low profile. The custom moldable fit eliminates the usual break-in period so you can walk out of a store and onto the trail. However, after five months of use, I don’t notice a significant difference in fit between the Forge and boots I’ve previously worn. Those willing to put their time into breaking in a new pair of boots may not see the heat moldable feature as an advantage, while adventurers looking for an instant best friend for their feet will be singing their praises.

Pros

- Custom heat-moldable fit

- Low profile

- Lightweight

- Waterproof

- Versatile

Cons

- Must attend fitting in person

- Laces loosen

Conditions:

I tested the Tecnica Women’s Forge as a member of the Trailspace Review Corps from October 2017 through February 2018 in and around the New Hampshire White Mountains. Temperatures during testing ranged from about -20 to 45 degrees Fahrenheit.

Jim51111 and I were lucky enough to do a side by side comparison of the Forge. Check out his review of the men's version.

Jim51111 and I fat biking in the Tecnica Forge for some side by side comparison

I wore them hiking in fall and winter conditions, and enjoyed snowshoeing and fat biking in the boots during the winter months. The Forge is described as a three-season boot (spring, summer, and fall). Accordingly, I hadn’t expected to get much use out of them in the winter. I was pleasantly surprised to notice, when I sat down to write this review, that I have yet to dust the cobwebs off of my go-to winter hiking boots (Salomon Quest GTX), having worn the Forge faithfully all winter long!

Snowshoeing in the Forge

Fit & Comfort:

The Forge is true to fit. I’m typically a size 8, which fit me perfectly. I wear a custom orthotic, and the Forge accommodates this without issue—I just removed the insoles that came with the boot. I’d say my feet are a standard width. The narrow profile of the Forge may not be a good fit for those with wide feet, but I find the fit to be ideal. I have just enough breathing room to feel comfortable without my foot sliding around in the boot. According to my bathroom scale, the pair weighs just two pounds.

The last that Tecnica used to construct the Forge (on the right in the below photos) is much more detailed than the standard model (on the left). This was a selling point to me. Knowing they are taking the time to fit the boot to something that more closely resembles a normal human foot, even before getting to the heat-moldable feature, makes me feel much more confident in the quality of this product.

Do I feel the difference on the trail though? I’ve never had any blisters or hot spots during my five months of testing, and my feet have been consistently comfortable.

Heat-Moldable Technology:

To my knowledge, Tecnica is the first to incorporate heat-moldable technology, the kind we often see in ski boot liners, into a hiking boot. The boot’s insole and ankle area mold to your foot, creating an instant custom fit that typically takes months of breaking-in and possibly the purchase of expensive insoles to achieve.

The fitting was so much fun. Being someone whose feet are chronically freezing, I felt like I’d stumbled into a spa for outdoor adventurers! The heat molding components are contained in what looks like a rolling suitcase. I imagine such a kit would appeal to retailers, as it can be stowed away when not in use, and travel between locations.

Heat-moldable technology

To mold the insole, they removed the insole from the boot and placed it in what looked and felt like a thin neoprene slipper. Once wearing the booties, I was strapped into a set of what I can only describe as inflatable clown shoes, which were then filled with hot air, almost like a blood pressure cuff on both feet, but not uncomfortable.

Insole heater (above) and bootie for molding the insole (below)

Insoles being heat-molded to my feet (below) as I experience zero gravity clown feet!

While the insole was molding to my foot, the boots themselves were heated. Once the insole heat-molding was complete, the insole was placed back into the hiking boot, now warm, and I laced up the boots and sat with them on my feet to allow the upper to mold around my ankles.

Heat-molding the insoles to my feet (above) while the Forge upper heats up (below)

I was told the heat-molding process can be repeated a few times. However, I’m unable to test this claim.

Once fitted to my feet, the boots were so comfortable I wore them out the door! The instant fit of the boot eliminates not only the uncomfortable breaking-in process, but also the mental angst that can accompany a new boot owner. Should I wear it outside? Can I return it? It’s rubbing this one spot on my heel…will that ever go away? Having confidence in a boot purchase from the minute I walk out of a store brings new meaning to the term retail therapy…and keeps me from getting cold feet (pun intended—sorry I just couldn’t resist).

Five months later, the boots are as comfortable and supportive as the first moment I wore them. The comfort has actually improved as the rest of the upper has broken in, specifically around the toe box, which isn’t custom moldable but breaks in over time. The Nubuck leather has a fantastic feel and is supportive without feeling too stiff.

During the fitting, I mentioned that I wore custom orthotics. The person completing the fitting suggested that while the insoles in the Forge would be an improvement over other standard insoles, I’d likely still need to wear my orthotics. This has proven to be true, which means I miss out on the custom feature of the heat-moldable insoles that come with the Forge.

However, it’s worth mentioning that the orthotics I wear are more than just the standard Superfeet insoles, or other such brand. They’re medically prescribed custom orthotics designed for my crazy feet. So, I don’t ding Tecnica for the fact that their insoles are not an adequate replacement.

Support:

The Forge offers support through the ankle without restricting movement. It’s a beefy enough shoe to wear trail spikes and snowshoes comfortably while the narrow profile keeps me from feeling cumbersome on technical portions of trail.

The first set of lace hooks at the ankle are self-locking, which is a pretty cool feature. It allows me to lace the ankles without losing tension through the forefoot.

Look...no hands! Self-locking lace hooks

My biggest complaint with the Forge, however, are the laces. No matter how I tie the laces, they consistently loosen through the ankle. I'm not sure how much of this issue is because of the laces themselves or the design of the tongue (which I describe later), which could be loosening the ankle as I hike.

It's not so much of a problem in the fall, when I can easily reach down to make adjustments and retie. However, it becomes a more significant issue in the winter when spikes or snowshoes place more strain on the ankles and the laces are often hidden under gaiters and therefore difficult to readjust. They rarely come untied, but if I hike more than 2 miles or so the ankles become noticeably loose and therefore less supportive.

Laces partially untied 0.7 miles in from the trailhead

Water Resistance & Breathability:

The Gore-Tex lining incorporated into the Forge ensures my feet remain dry on wet or snowy days. Never once have I found myself complaining of wet feet, either from lack of breathability or waterproofing. That being said, I started wearing the Forge in October so haven’t tested it during summer months.

Staying dry in snowy conditions

As they’re technically not designed to be winter boots, I need to keep moving when wearing the Forge during winter months. My feet tend to get cold if I do too much standing around in the snow…good motivation to keep moving!

Traction:

After five months of consistent use, the Vibram sole on the Forge is showing no signs of wear. I love the traction it provides along with enough flexibility through the toe to grip technical terrain.

Vibram sole from the side (above) and bottom (below)

Because of the low profile, I’ve found I have to go down a size in my Hillsound Trail Crampons. This is not a problem, just something to be prepared for.

Forge in Hillsound Trail Crampons

Ease of Use:

Once the fitting is complete, the Forge is just as straightforward as any other hiking boot. It incorporates a wrap-around tongue, which reminds me of a ski boot liner. I like this feature, as the edge of the tongue tucks in nicely to the ankle of the boot. Normally I’d expect this design might rub, but that hasn’t been the case, likely because of the heat-molding through the ankle.

Wrap-around tongue

Construction and Durability:

In the past five months, these boots have carried construction supplies a quarter mile into the woods and built a yurt, joined me on my daily pre-work hike or snowshoe, and accompanied me on longer weekend trips hiking, snowshoeing, and fat biking. And you’d never know that by looking at them.

Photo taken on the day I wrote this review—minimal wear after five months

I’ve experienced no issues associated with wear. The Gore-Tex waterproofing still does its job and the boot itself has held its shape, remaining supportive and comfortable.

The Forge retails for $250, which is fairly comparable to similar products. The Salomon Quest GTX, for example, retails for $230. Assuming they continue to hold up over time (I’ve had my Salomons for seven years now) I consider the price fair. However, this is a matter each reader should weigh for his/herself.

Overall Impressions:

The Forge is a quality hiker likely to be most enjoyed by those who are drawn to lightweight, low profile boots. My first outdoor love was long distance running, and because of this my feet still gravitate toward hiking boots that are akin to trail runners. So the Forge is a great fit for me.

The heat-moldable ankle and insole set the Forge apart from other hiking boots. It creates an instant break-in process that could be a game changer for some—those whose feet don’t often fit standard boots or can’t afford an extended break-in process. I’d love to see the heat-moldable technology extend beyond the ankle—through the toe box if possible. I’m also a huge fan of bringing gear shopping offline, encouraging more face-to-face interactions between gear experts and outdoor adventurers. The custom fitting provides an ideal format for this.

However, those who do not live near an authorized retailer may lose out. Others may prefer taking their time to break in a new boot and not see the value in an instant fitting. Personally, I’m a fan of the heat moldable-technology. It reduces my risk of buyer’s remorse (or angst), and allows me to enjoy the boot from the moment it hits the trail.

The only change I’d really like to see moving forward is to switch to laces and/or tongue design, whichever is contributing to the ankle loosening so easily. It’s a simple fix that would go a long way for my ankles!

Thanks to the folks at Tecnica and Trailspace for the opportunity to test and review the Forge!

Source: received for testing via the Trailspace Review Corps

(Sample provided by Tecnica for testing and review)

On my pair of boots the rand came unstuck along a half-inch section of the toe box after just one week (20 miles of use)!!!! Tecnica replaced them, but this does not bode well for build quality or longevity.

Other big problem is the heel box. There is a heavily stitched seam running up the heel, meaning that any space/slack results in rubbing, especially on steep uphill going. Result: blisters. And this is only going to get worse over time as the boots loosen up. Frankly, putting a seam here is a major design error.

So I now have a nearly new pair of very expensive boots that I only use for light local walking because I have no faith in the long distance durability or comfort.

Pros

- Great grip on all surfaces

- Nubuck leather resists abrasions and dirt

Cons

- Build quality

- Heel seam = blisters (unless very heavy socks are worn)

- Thin laces keep coming loose

- Price

So after a few more months of use, and getting over my initial issues, I have updgraded my review to two stars (from one).

The boots have been used for a mix of steep and rocky mountain and 'average hill' hikes. On both loose gravel and slick rock surfaces. Mostly in good (and often extremely hot) weather in France and Italy.

Most amazing (good) aspect of these boots is the grip, on all surfaces. It really is astonishing. The soles look like they are going to be durable long term too.

The boots are also totally waterproof. And relatively cool, even in hot weather.

The heel blister issue has been 'resolved' by inserting a strip of duct-tape on the heel section. The duct-tape is difficult to get into the boot due to the restricted opening (the particular design of the forge) and generallt takes 3-4 strips (wasted) before I get one properly positioned and stuck down without ripples or folds. The duct-tape will hold for 20-mile hike, no problem. Sometimes get two hikes out a strip beforeit has to be replaced. It's just really, really sad that I have to resort to this overcome a design flaw in such an expensive boot.

As others have noted, the laces are a problem. I double-knot after the first half-mile (once I'm sure that I have the lacing correct) but there is often still the need to retighten during a walk. Maybe some different laces would help (the standard laces here in Europe are very thin waxy string type, not like the ones in photos in the other reviews here). But the narrow lace lugs will limit how thick the laces can be.

Overall, these would be my dream boot except for heel stitching and the laces (and the price).

Source: bought it new

Price Paid: 250 Euros

Your Review

Where to Buy

You May Like

Specs

| Men's | |

|---|---|

| Price |

Historic Range: $174.73-$280.00 |

| Weight |

595 g |

| Women's | |

|---|---|

| Price |

MSRP: $250.00 Historic Range: $250.00-$280.00 |

| Weight |

520 g |